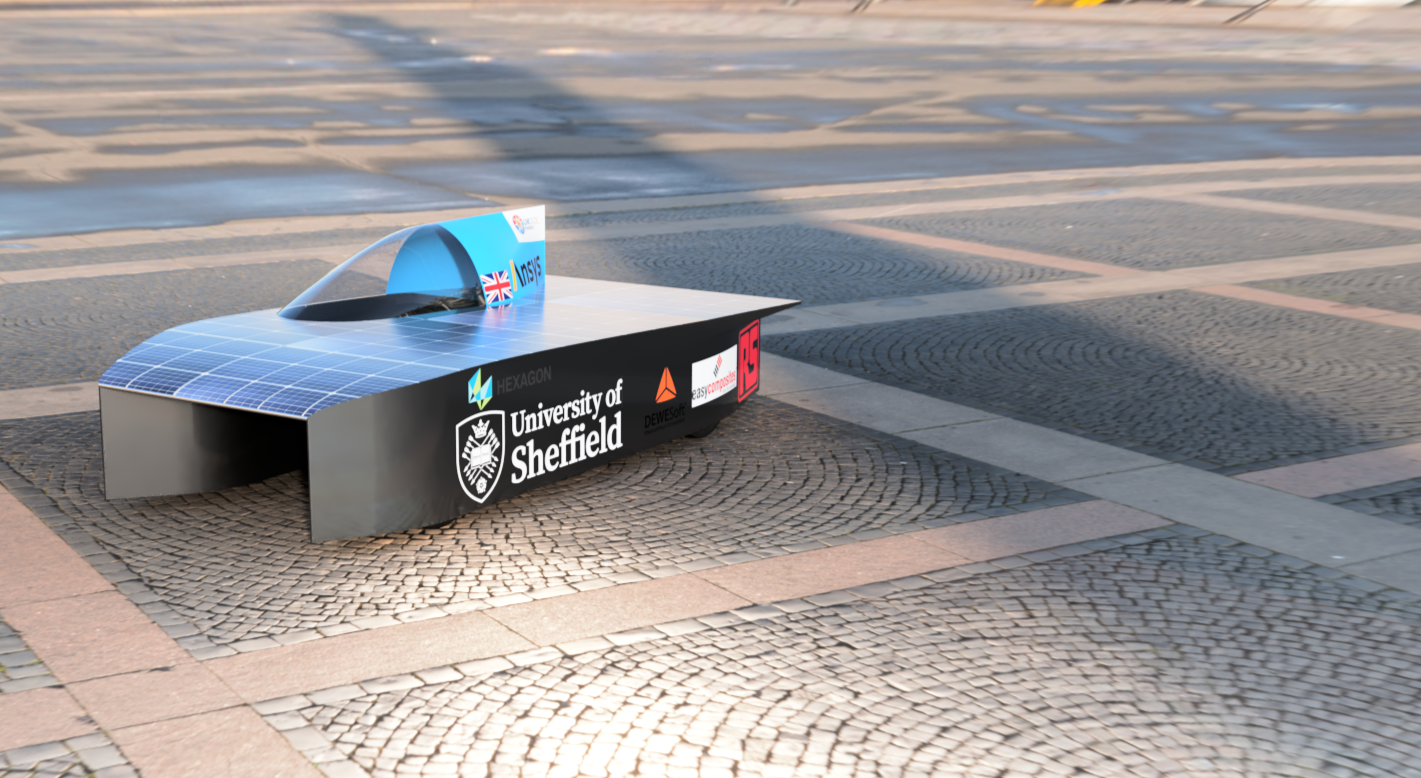

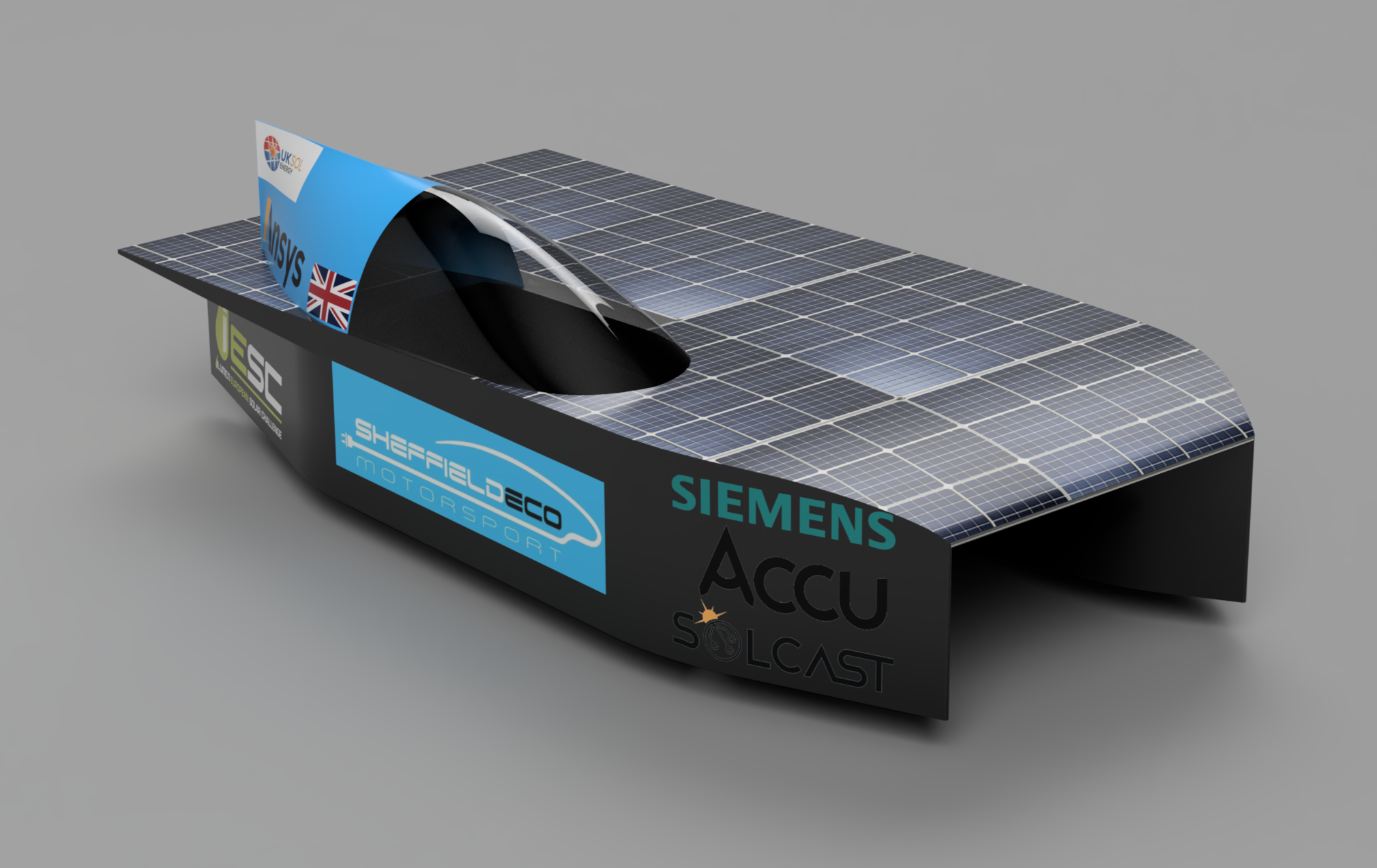

Our 3rd generation car is a radical change from the cars preceding it. With a competition change the full design needed a rethink as with new rules come new constraints. Over the 24/25 year the team gained understanding for the new regulations finding opportunities' for design innovations to maximise performance.

SEM-03

24/45 Season:

Over the past year, our team has taken a deep dive into the new competition’s regulations to fully understand our design limitations and identify opportunities to maximize efficiency and performance. We dedicated the year to intensive research and development, laying the groundwork for our goal of competing in 2026. Throughout this process, we produced detailed CAD models with numerous iterations across key components, developed and simulated solar arrays in line with strict power and battery constraints, and carefully planned the integration of essential lighting and sensor systems. In addition, we designed the vehicle’s suspension and braking systems and began formulating strategic plans for how the car will perform during competition.

What have we achieved so far?

All lab based images may be a re-enactment or depiction of lab activities.

-

Last year was interesting. We manged to design the vast majority of the parts that our sub team is responsible for. The chassis was finalised by the end of the year and the designs have been passed to the welder for manufacture. The bodywork has been optimised to minimise drag as much as possible through the use of CFD sims.

-

In the 2024/25 year, our team placed a strong emphasis on the design and development of all our vehicle dynamics components. Much of our effort was dedicated to refining the vehicle systems, from the steering column to the suspension and braking assemblies. This focus allowed us to achieve a high level of detail and precision in our designs, ensuring that each subsystem was thoroughly planned and validated before moving toward manufacturing. The commitment and collaboration shown by the team were evident in the quality of the work produced, with every member contributing to the success of these complex projects. By investing significant time in careful planning and documentation, we have laid a solid foundation that will make the upcoming manufacturing phase far more efficient and streamlined. The progress achieved last year has not only strengthened our technical capabilities but also positioned us well for the challenges ahead in 2025/26.

Together, these efforts ensure that the vehicle’s dynamics systems work cohesively to provide precise control, safety, and efficiency on the road.

-

Powertrain has focused on developing detailed risk assessments to support the purchase and development of our two in-hub motors and a bespoke battery system. The team has utilized advanced battery simulation tools to analyze and predict the battery’s performance, size, and efficiency. A major part of Powertrain’s work also involves procuring essential components from suppliers, including VESCs and in-hub wheel motors, to ensure reliable and high-quality system integration. By liaising with companies in the battery industry, Powertrain has been able to clearly define the cooling requirements for the system, optimizing thermal management while eliminating unnecessary drag caused by excess vents and cooling channels.

-

The 24/25 year was a major step forward for the Embedded Systems team. Designing a safe, reliable, and energy-efficient low-voltage system from scratch forced all of us to learn quickly and think more strategically. We spent the year researching, planning, and building out systems that were completely new to us. We developed the plan for our exterior lighting system, which will make the car road legal and ready for all conditions during the 24-hour race in Belgium. We also planned the implementation of our in-car communication system using the CAN protocol. Even though these systems are not built yet, we gained a strong technical understanding of how they work and what it will take to execute them properly. A major advantage last year was the opportunity to visit the Turkish solar team, ITU. With more than twenty-one years of experience, they gave us valuable advice and insight that helped us avoid unnecessary mistakes and refine our approach. These milestones form the foundation we’re building on now as we prepare for iESC.

-

The Race Strategy & Simulation (RSS) team plans how the car is driven during competition and validates design decisions. We build models of vehicle dynamics, energy use, and track conditions to optimise lap times and overall race strategy. Our tools in MATLAB and Simulink include solar-input forecasting via APIs, battery behaviour models, a lap time simulator, and a driver-in-loop simulator. We also develop algorithms to decide when to pit and how much to charge. By testing and validating our models with real data, we ensure the car runs as efficiently as possible throughout the race.